Hot tapping services play a critical role in modern industrial operations, especially where shutting down pipelines or systems is not an option. In the UAE—particularly in Dubai, Abu Dhabi, and Ajman—hot tapping companies provide specialized solutions that allow new connections, repairs, or modifications to be carried out on live pipelines without interrupting operations.

This article explains hot tapping services, their importance, how to choose the right provider, and an overview of hot tapping companies across the UAE.

Understanding Hot Tapping Services

Hot tapping is an advanced industrial technique used to create branch connections on pressurized pipelines or tanks while they remain in operation. This method eliminates the need for shutdowns, making it highly valuable in industries where continuous flow is essential.

Hot tapping services are commonly used in:

- Oil and gas pipelines

- Petrochemical plants

- Water and wastewater networks

- District cooling systems

- Industrial process pipelines

By using specialized equipment and trained technicians, hot tapping companies ensure safe and precise connections without compromising system integrity.

What Is Hot Tapping?

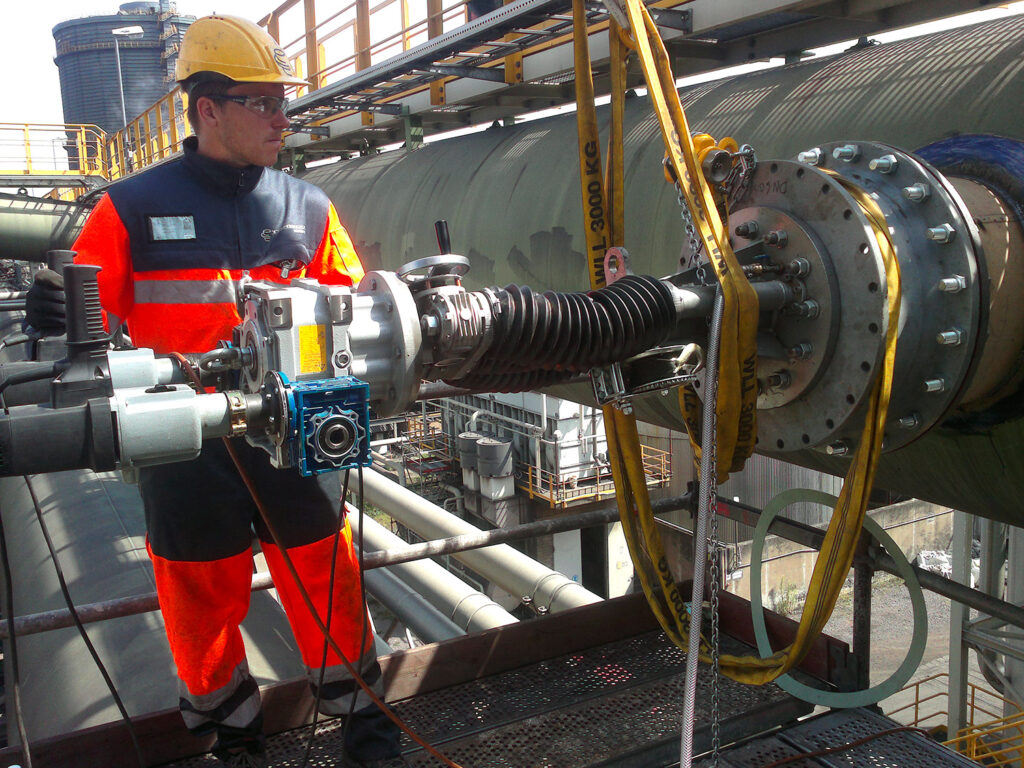

Hot tapping, also known as live tapping or pressure tapping, is the process of drilling into a pressurized pipe or vessel to install a new connection. The procedure involves mounting a tapping machine, cutting through the pipe wall under controlled conditions, and installing a fitting that maintains pressure containment.

Key components used in hot tapping include:

- Tapping machine

- Cutter or hole saw

- Isolation valve

- Reinforced fitting

This process allows industries to expand or modify their pipeline systems efficiently and safely.

Importance of Hot Tapping in the Industrial Sector

Hot tapping services are essential for industries that cannot afford downtime. Shutting down pipelines can result in significant financial losses, safety risks, and operational delays.

Key benefits of hot tapping include:

- No interruption to system operations

- Reduced downtime and operational costs

- Enhanced safety compared to traditional shutdown methods

- Faster project completion

- Environmentally safer pipeline modifications

Because of these advantages, hot tapping is widely used across industrial facilities in Dubai, Abu Dhabi, Ajman, and throughout the UAE.

Criteria for Choosing the Best Hot Tapping Services

Selecting the right hot tapping company is crucial for safety and project success. Below are the most important factors to consider:

Experience and Expertise

Experienced hot tapping companies have trained technicians who understand pipeline materials, pressure conditions, and safety requirements. A proven track record across multiple industries ensures reliable and efficient execution.

Equipment and Technology

Modern hot tapping services rely on advanced machinery and precision tools. Companies that invest in updated technology can deliver accurate results while minimizing risks.

Safety Standards and Protocols

Hot tapping involves working on live systems, making safety non-negotiable. The best hot tapping services in the UAE strictly follow safety standards, conduct risk assessments, and ensure full compliance with industry regulations.

Hot Tapping Companies in Dubai

Dubai is a major industrial hub, hosting numerous hot tapping companies that serve sectors such as oil and gas, construction, water treatment, and district cooling. Hot tapping services in Dubai are known for their technical expertise, strict safety compliance, and ability to handle complex live pipeline operations efficiently.

Hot Tapping Services in Abu Dhabi

Abu Dhabi’s industrial sector, particularly oil and gas, relies heavily on professional hot tapping services. Hot tapping companies in Abu Dhabi are experienced in high-pressure pipeline environments and large-scale industrial projects, ensuring minimal disruption and maximum operational safety.

Hot Tapping Services in Ajman

Although smaller in scale, Ajman also offers reliable hot tapping services for manufacturing facilities, utility pipelines, and industrial plants. Hot tapping companies in Ajman provide customized solutions tailored to project size, pressure conditions, and industry requirements.

Comparing Hot Tapping Services in the UAE

When evaluating hot tapping services in Dubai, Abu Dhabi, Ajman, or anywhere in the UAE, consider the following factors:

Cost: Competitive pricing with transparent quotations

Service Quality: Proven results and technical accuracy

Safety Compliance: Adherence to UAE and international safety standards

Customer Satisfaction: Positive client feedback and long-term partnerships

Choosing the right hot tapping company ensures efficient project execution and long-term system reliability.

Conclusion

Hot tapping services are an essential solution for industries that require safe, efficient pipeline modifications without shutdowns. With experienced hot tapping companies operating across Dubai, Abu Dhabi, Ajman, and the UAE, businesses can achieve cost-effective and reliable results while maintaining continuous operations.

If you are looking for professional hot tapping services or trusted hot tapping companies in Dubai, Abu Dhabi, Ajman, or anywhere in the UAE, selecting an experienced provider with strong safety standards and modern equipment is key to project success.